Chaney News

April 6, 2022News, Community

8 Ways Chaney Invests in our Planet

Author: Madison Sloan

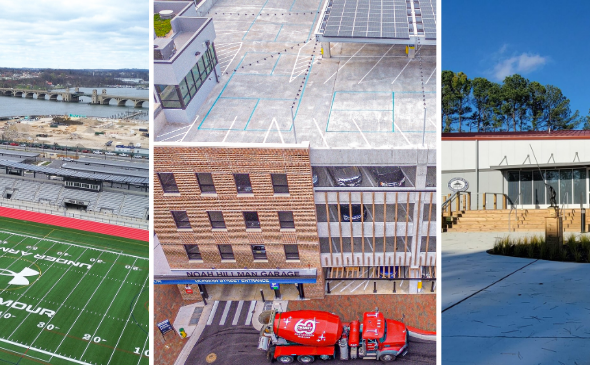

As one of the largest producers of concrete, sand, and gravel in the mid-Atlantic region, Chaney Enterprises is also one of the region’s largest employers. Therefore, our roots in the community are deep, enduring, and built on trust. So is our commitment to preserving the health of the land—we recognize that the environment must be treated with respect and with an eye to the future.

We employ best industry practices in aggregate and concrete operations, land management, mining, and reclamation. To us, making a lasting impact means that we can sustain our current relationship and enjoyment with the natural environment, without compromising the needs of future generations.

Here’s 8 ways that Chaney invests in the future of our planet each and every day:

1. Recycled Concrete

One of the most sustainable features of concrete is its ability to be recycled when it is finished with its long service life. Chaney Enterprises alone processes more than 100 million pounds of recycled concrete a year. By diverting construction waste from landfills, the use of recycled concrete not only helps protect the environment, but also saves money by reusing material, and avoiding disposal fees. Recycled concrete is made on site several of our locations by crushing returned or demolition concrete.

2. CarbonCure

By introducing recycled CO2 into our concrete mix designs using CarbonCure technology, we’ve managed to save 2.7 million pounds of CO2 from being released into the environment. That’s equivalent to 1,571 acres of forestland absorbing CO2 for a year! Learn more about CarbonCure technology and how we’re using it at 13 of our concrete plants: https://www.chaneyenterprises.com/sustainability.

3. Water Discharge Systems

Our patent-pending Hydro-carbonic Purification System allows ready-mix concrete producers and concrete manufacturers to recycle process water in real time. The recycled water our system creates meets ASTM C1602/1602M-18 standard specification for mixing water used in the production of hydraulic cement concrete, effectively creating zero-water discharge concrete plants. At this time, Chaney has 5 sites that are considered zero-water discharge.

4. Recycled Land

Our goal is to leave a mine site in better condition than how we found it. Once we are finished mining land, we always reclaim it. Reclaiming land means that we restore it to its original use, or to a condition supporting an approved alternative. We’ve even created ideal habitats for native bees before! While some areas become wetlands to serve as habitats for plants and animals, other mine sites have been reclaimed as farmland, green space, housing developments, recreational facilities and even an 18-hole golf course.

5. Going Paperless

Did you know that the average office worker generates about two pounds worth of mixed paper products every day and uses about 10,000 sheets of paper each year!? Imagine how much paper would be generated with a company that makes thousands of deliveries a day!

Back in 2018, Chaney Enterprises committed to reducing the use of paper in our daily work processes. Through the use of electronic ticketing systems, electronic billing, the Chaney App, employee self-service technology and email instead of paper mail, we have been able to reduce the use of paper tremendously. Customers can now access their tickets in three paperless ways: customer app, email, and the “Pay Now” link on the homepage of our website.

6. Recycling Program

Employees at Chaney’s headquarters in Gambrills, MD have become true experts when it comes to recycling! Each employee’s office or cubicle has its’ own recycling bin with helpful signage about what’s recyclable and what’s not.

Furthermore, the company is now collecting old batteries to ensure they’re properly recycled. The company plans to roll out recycling programs at each of its’ locations in the near future.

7. Making use of Alternative Energy

Chaney Enterprises has replaced fossil fuel oil with renewable biofuel in our Infern-O-Therm hot water boilers. In addition to the boilers, Chaney Enterprises uses biofuels in our many off-road vehicles. Chaney also has an opportunity for a large energy offset by using solar panels at their flagship Waldorf, MD location.

8. Cement Substitutes

We all know that cement production emits carbon dioxide and other greenhouse gases into Earth’s atmosphere. Although Chaney Enterprises does not currently produce cement, we have found ways to reduce the amount of cement needed in our ready-mix concrete.

Fly ash, a by-product of coal combustion, can be used to replaced up to 50% of the Portland cement typically found in a concrete mix, while also improving the workability of concrete. We also make use of slag, an industrial by-product of an iron blast furnace. Slag is also known in the industry as having such benefits as improved workability, higher long-term compressive strength, consistent performance and easier finishability.