Sustainability

SUSTAINABILITY: PAVING THE WAY TO A GREENER FUTURE

At Chaney Enterprises, we are committed to building a sustainable future by reducing our environmental impact and leading the way in responsible practices within the ready-mix concrete and aggregate industry. Our sustainability efforts focus on reducing Global Warming Potential (GWP), a critical measure of how greenhouse gas emissions contribute to global warming. We reduce GWP through our innovative Ever Concrete Series™, a custom designed, low-carbon concrete that minimizes environmental impact without sacrificing quality or performance.

Real Results

HILLMAN GARAGE IN ANNAPOLIS, MD

Featured a 1L low carbon cement and 40% slag mix with recycled water, significantly reducing our GWP and winning us a sustainability award from the Slag Cement Association.

LOOKING FOR AN EPD?

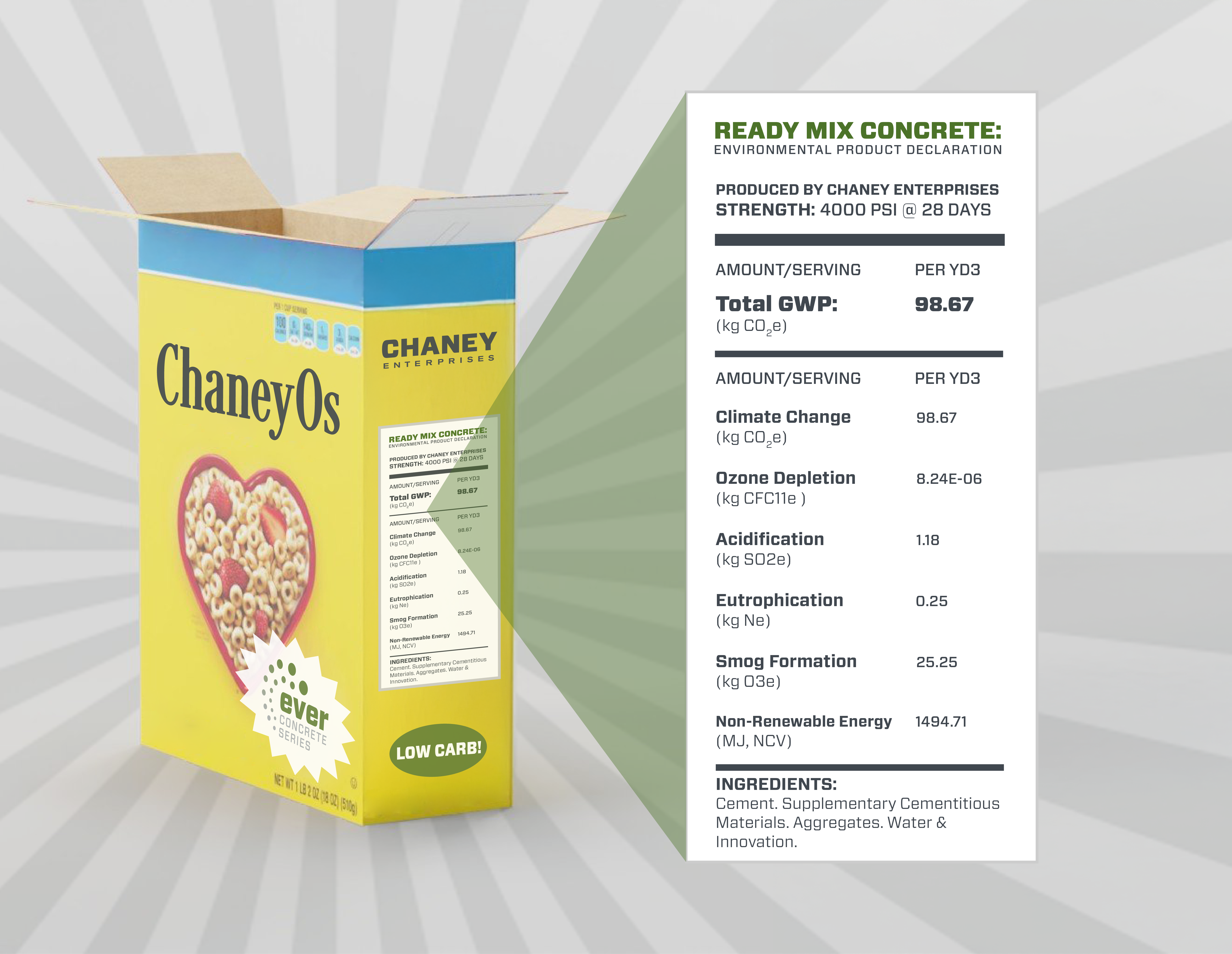

At Chaney Enterprises, we understand the importance of transparency and sustainability in construction. That’s why we provide Environmental Product Declarations (EPDs) for all our concrete and aggregate products.

EPDs give you a clear picture of the environmental impact of the materials you’re using, ensuring they meet your project’s sustainability requirements and align with your carbon reduction goals.

With Chaney, you can trust that our products not only deliver on performance but also contribute to a more sustainable future.

EVER CONCRETE SERIES™

The Ever Concrete Series™ is designed to meet the growing demand for low-carbon concrete, helping you achieve sustainability goals without compromising strength or durability. Our unique calculator helps customers and partners understand the environmental impact of their concrete mix and choose the best solutions to reduce GWP.

FIND YOUR GLOBAL WARMING POTENTIALS (GWP)

A DEDICATED TEAM OF EXPERTS

Our in-house team of ACI-certified professionals focuses on research, development, innovation, and sustainability to support your project goals. With decades of expertise, they collaborate closely with partners and customers to design custom concrete mixes that are environmentally friendly and high-performance.

SUSTAINABILITY MISSION STATEMENT

At Chaney Enterprises, we are passionate about creating sustainable facilities, providing environmentally friendly products, and reclaiming land for a new purpose. By embracing innovative technologies and sustainable practices, we’re paving the way to a greener future.

INTERESTED IN LEARNING MORE?

The Ever Concrete Series™ can help you build a more sustainable future. Contact us below to get started:

Chaney’s Ever Concrete Series was a game-changer for our project. We reduced our carbon footprint and stayed on budget

without compromising on quality.