Products

Concrete

Concrete

Parking Lots

Parking Lots

Parking Lots

Less expensive, more environmentally friendly, easier to maintain and long lasting... why would you even consider another pavement?

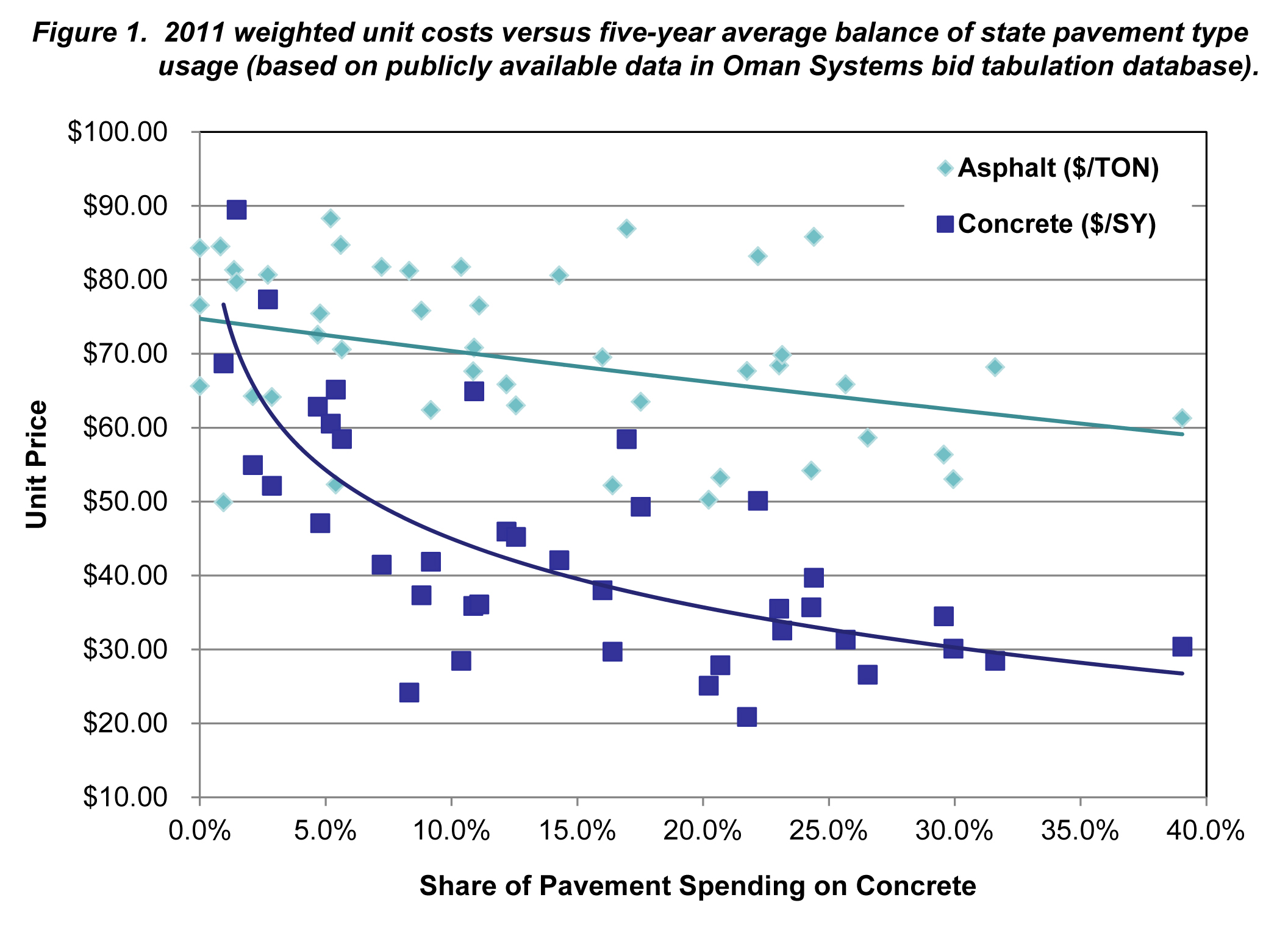

It’s no secret that increased competition lowers costs. By allowing concrete to compete against asphalt, data shows that both concrete and asphalt pricing drops. Figure 1 shows how this has happened for roads and the same is true for parking lots.

Take the Concrete Challenge!

Get a Free Concrete Parking Lot Design

With the Geotechnical Report and CAD drawings we can return to you a full plan with a jointing pattern designed in accordance with ACI 330, Guide for the Design and Construction of Concrete Parking Lots. If the geotechnical report and CAD drawing are not available, we can work with what you have.

Specify Concrete with an Asphalt Alternate

By specifying concrete as the default with an asphalt alternate, you will encourage more bids. More bids mean more competition. More competition means lower costs. We ask for the concrete as a default, because asphalt bids will come no matter what. When concrete is buried in the plans, it is our experience that it is often overlooked.

Evaluate the Bids

Let the market decide. You may be willing to pay more for a better pavement, or it may be all about initial costs. Either way, you can sit back and watch competition work to your benefit.

Take the Savings to the Bank

No matter if your focus is life cycle costs or initial costs, increased competition will give you a savings you can bank on.

Need more information? We also offer a detailed education program providing Professional Development Hours (PDH’s) showing how concrete can change the way you look at paving.

Get started now!

Download our Concrete Parking Lot brochure here.